The Best Commercial Refrigeration Repair Business in Toronto Revealed

The Best Commercial Refrigeration Repair Business in Toronto Revealed

Blog Article

Maximizing Efficiency: Commercial Refrigeration Repair Service Techniques for Cost-Effective Solutions

Assessing Refrigeration System Performance

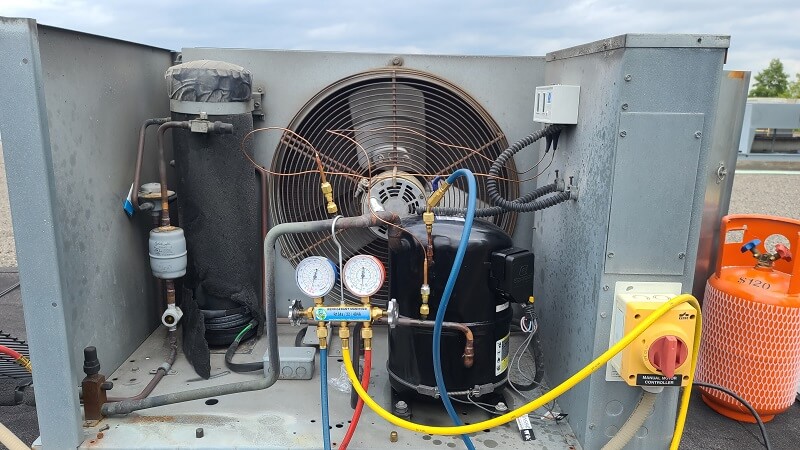

To efficiently examine the efficiency of an industrial refrigeration system, it is important to carry out extensive assessments of its operational specifications and vital elements. The initial step in assessing system performance is examining the functionality of the compressor. The compressor plays a critical duty in maintaining the preferred temperature within the refrigeration unit. Issues with the compressor can result in poor cooling, temperature level variations, and raised power intake. Carrying out routine examinations and performance tests on the compressor can help recognize possible problems early and stop expensive break downs.

Furthermore, evaluating the condenser and evaporator coils is critical. Dirty or clogged up coils can substantially affect the system's effectiveness by preventing warm transfer processes. Cleaning up the coils on a regular basis and ensuring appropriate air flow around them can maximize the system's cooling capacity and decrease energy consumption. Keeping track of refrigerant levels and pressures is likewise essential in evaluating system efficiency. Low cooling agent degrees or irregular stress can indicate leaks or malfunctioning components that need prompt attention to avoid system failings and expensive repair work. By systematically reviewing these key parts and operational specifications, organizations can ensure their industrial refrigeration systems run at peak performance degrees, lessening downtime and maximizing energy efficiency.

Implementing Preventative Maintenance Actions

Assessing the performance of an industrial refrigeration system supplies valuable understandings that can educate the implementation of preventative upkeep procedures important for sustaining ideal functionality and long life. Preventative maintenance is an aggressive approach focused on determining and addressing prospective problems prior to they escalate right into pricey problems that interrupt procedures. By establishing a regular upkeep routine, refrigeration systems can run efficiently, lowering energy intake and lessening the risk of unexpected malfunctions. Key preventative maintenance actions include evaluating and cleansing condenser coils, inspecting refrigerant degrees, making sure proper air movement, and adjusting temperature level controls. In addition, keeping track of temperature and humidity levels, examining door seals, and resolving any type of unusual noises or smells without delay are necessary action in preventative maintenance. Carrying out these measures not only extends the lifespan of the devices however also improves food safety by maintaining regular storage temperature levels. Inevitably, buying preventative maintenance measures is a cost-effective approach that helps services prevent expensive repair work and downtime, guaranteeing continuous and dependable refrigeration system efficiency.

Identifying Common Refrigeration Issues

One of useful content the key elements in keeping business refrigeration systems is without delay identifying typical problems that may develop throughout their procedure. One common problem is insufficient cooling, commonly brought on by unclean condenser coils or a malfunctioning compressor. Regular cleaning of the condenser coils and ensuring appropriate ventilation around the device can help avoid this issue. One more usual problem is refrigerant leakages, which can result in ineffective air conditioning and potential ecological dangers. Keeping track of cooling agent degrees and conducting routine evaluations for leakages can help reduce this trouble. In addition, defective gaskets on doors, leading to air leaks, can trigger the refrigeration system to function tougher to maintain the preferred temperature. Routine examination and substitute of damaged gaskets are important to prevent power waste. Uncommon sounds such as knocking, clanking, or hissing can indicate underlying mechanical problems that need immediate interest to avoid further damages. By immediately identifying and dealing with these typical refrigeration problems, organizations can make sure the effective procedure of their systems and lessen pricey repairs.

Utilizing Energy-Efficient Fixing Methods

When considering industrial refrigeration repair, applying energy-efficient methods is paramount to enhancing the system's performance and minimizing functional costs. Among the key methods in achieving energy performance is ensuring that the refrigeration system is effectively preserved. Normal maintenance, such as cleaning up condenser coils, examining for cooling agent leakages, and adjusting temperature setups, can significantly boost energy effectiveness.

An additional energy-efficient repair method is upgrading his response to high-efficiency elements - Toronto commercial refrigerator repair. By replacing older, less reliable get rid of energy-efficient options, such as ECM fan motors commercial refrigerator repair or LED lighting, organizations can lower power intake and reduced utility prices. Additionally, installing programmable thermostats and energy management systems can aid regulate temperatures better, stopping unneeded power use

In addition, maximizing the system's insulation and securing any kind of leaks can also add to energy cost savings. Proper insulation assists preserve consistent temperatures within the refrigeration unit, minimizing the workload on the system and improving overall efficiency. By incorporating these energy-efficient repair work techniques, organizations can not only decrease their environmental impact yet additionally attain long-term expense financial savings.

Optimizing Refrigeration System Life Expectancy

To make sure the durability and ideal performance of industrial refrigeration systems, keeping energy-efficient repair practices is important, with a focus currently shifting towards optimizing the refrigeration system life expectancy. Enhancing the life expectancy of a refrigeration system includes aggressive upkeep, prompt repairs, and adherence to manufacturer standards.

Furthermore, spending in high-quality parts and elements during fixings and replacements can enhance the longevity of the refrigeration system. By focusing on positive upkeep and making use of top quality parts, businesses can optimize the life expectancy of their business refrigeration systems, inevitably lowering downtime and operational expenses.

Verdict

In conclusion, by on a regular basis examining refrigeration system performance, applying preventative maintenance measures, determining usual refrigeration issues, using energy-efficient fixing techniques, and maximizing the system's life expectancy, organizations can optimize performance and reduce expenses related to commercial refrigeration repair work. These cost-efficient remedies help to guarantee that refrigeration systems operate at peak efficiency, inevitably leading to enhanced efficiency and earnings for services over time.

When considering business refrigeration repair work, carrying out energy-efficient strategies is paramount to enhancing the system's performance and reducing operational prices.To make sure the durability and optimal performance of industrial refrigeration systems, preserving energy-efficient repair service methods is crucial, with an emphasis currently moving in the direction of maximizing the refrigeration system life expectancy. Enhancing the life expectancy of a refrigeration system entails positive upkeep, prompt repair services, and adherence to maker guidelines.

Report this page